- HOME

- PRODUCTS

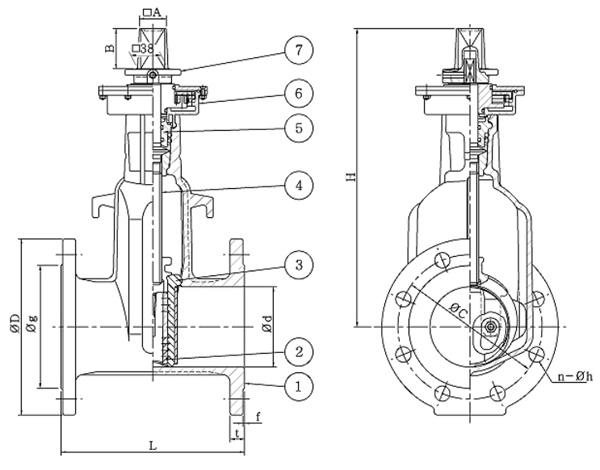

- Indicator Type Mono design Resilient Seated Gate Valves

Warning: mysql_real_escape_string() [function.mysql-real-escape-string]: Access denied for user: 'nobody@localhost' (Using password: NO) in /home2/shinjinvalve/public_html/mobile/sub/sub_header.php on line 132

Warning: mysql_real_escape_string() [function.mysql-real-escape-string]: A link to the server could not be established in /home2/shinjinvalve/public_html/mobile/sub/sub_header.php on line 132

Indicator Type Mono design Resilient Seated Gate Valves

Design features (Characteristic)

Three innovation

1. Integral strucure without bolt clamp

2. Perfect corrosion prevention

3. Automated robot epoxy resin powder coating

Corrosion protection

- Integral strucure design of no bolt clamp on value body and cover. No bolt hole on the valve body.

- Valve stem bearing by gearing lock (Bayonet). No bolt hole in valve stem bearing and packing box.

- No exposed surface on SRS-‚Ö¢.100% epoxy resin powder painting on internal.external is possible, and this is 100% corrosion prevented compatible to Ministry of Environment hygienic stability standard.

Strength

- Integral structure minimize valve weight, increase mechanical strength, to guarantee long valve lifespan.

Sealing geometry

- Integral structure with no gasket between body and cover, solving valve body water leak problem fundamentally.

- Sandwich structure of two independent rubber seated is excellent in water stop.

- Two rubber seated double beat stop water in the valve.

Function

- New structure and numbers of guides of valve guarantee the minimum operation power.

- Valve disc finger shim guarantee perfect operation even in big load.

- Double sealing (O ring) method of valve stem bearing provides absolute stability.

- Valve indicator provides innovation to water management efficiency.

Construction

Material

| No | Description | Material |

|---|---|---|

| 1 | BODY | Ductile iron GCD450 |

| 2 | DISC | Ductile iron GCD450 |

| 3 | DISC SEAT | Rubber EPDM |

| 4 | STEM | Stainless steel STS410 |

| 5 | PACKING BOX | Brass |

| 6 | INDICATOR BOX | ASS’Y |

| 7 | CAP | Ductile ironÔºö GCD450 |

Dimensions

Flanges to KWWA, DIN F4 and F5, GOST, SABS, AS, BS and AWWA standards

| size(√òd) | √òD | √òC | √òg | n-√òh | L | t | f | A | B | H | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| standard | Indicator | ||||||||||

| 80 | 200 | 160 | 133 | 4-19 | 203 | 18 | 2 | 33.5 | 50 | 310 | 341 |

| 100 | 220 | 180 | 153 | 8-19 | 229 | 18 | 2 | 33.5 | 50 | 342 | 372 |

| 150 | 285 | 240 | 209 | 8-23 | 267 | 22 | 2 | 33.5 | 50 | 428 | 459 |

| 200 | 340 | 295 | 264 | 8-23 | 292 | 22 | 2 | 33.5 | 50 | 515 | 545 |

| 250 | 395 | 350 | 319 | 12-23 | 330 | 24 | 2 | 33.5 | 50 | 611 | 640 |

| 300 | 445 | 400 | 367 | 12-23 | 356 | 24 | 3 | 33.5 | 50 | 695 | 723 |

| 350 | 506 | 460 | 427 | 16-23 | 381 | 26 | 3 | 32 | 70 | 877 | 909 |

| 400 | 565 | 515 | 477 | 16-28 | 406 | 27 | 3 | 32 | 70 | 959 | 990 |

| 500 | 670 | 620 | 582 | 20-28 | 457 | 29 | 4 | 32 | 70 | 1137 | 1169 |