- HOME

- PRODUCTS

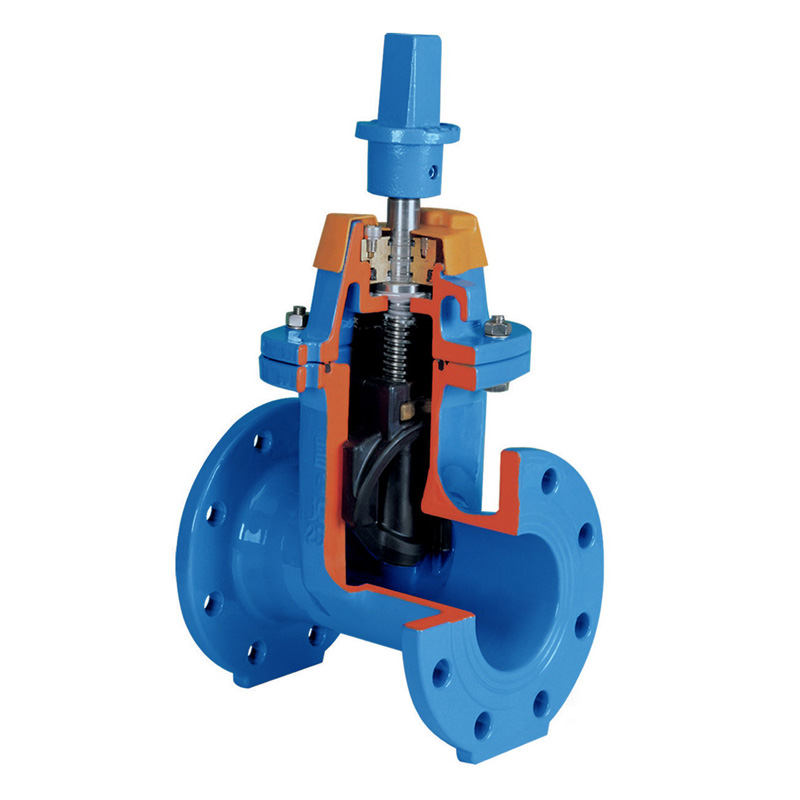

- Resilient Seated Gate Valves (AWWA C 515)

Warning: mysql_real_escape_string() [function.mysql-real-escape-string]: Access denied for user: 'nobody@localhost' (Using password: NO) in /home2/shinjinvalve/public_html/mobile/sub/sub_header.php on line 132

Warning: mysql_real_escape_string() [function.mysql-real-escape-string]: A link to the server could not be established in /home2/shinjinvalve/public_html/mobile/sub/sub_header.php on line 132

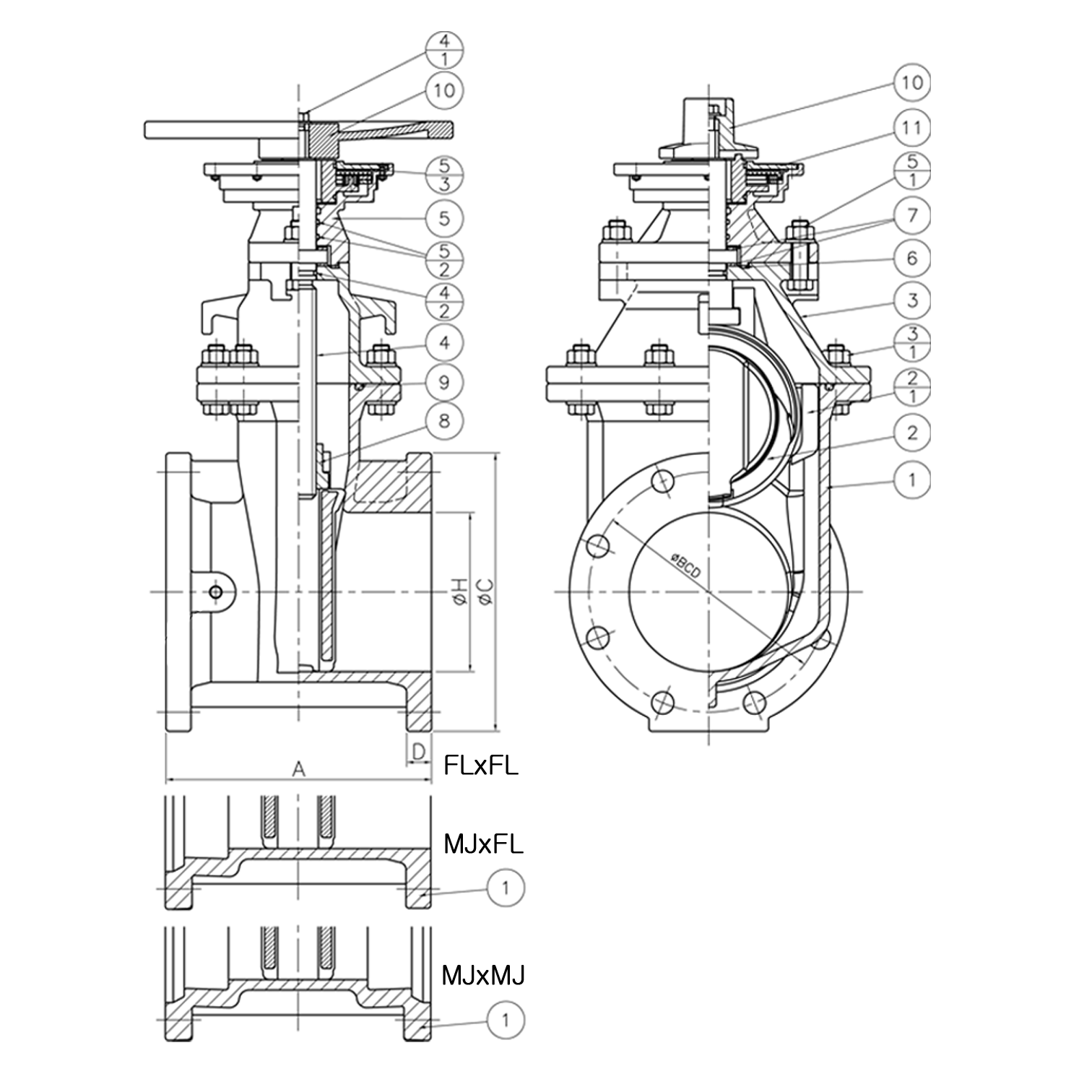

Resilient Seated Gate Valves (AWWA C 515)

Design features (Characteristic)

- Manufactured in accordance to AWWA C515 Standard

- Easily check the opening and closing of the valve

- The main body was manufactured of high srength ductile-iron in accordance with ASTM A536

- All surfaces of the main body was epoxy resin powder coated in accordance with AWWA C550 Srandard

- An even bottom of the body and a double soft seal enhanced the water stopping capability

- The stem was made of high strength stainless steel 304 to enhance corrosion resistance

- Enhanced capability of the valve in the high pressure by application of wedge structure twin seal

- Enhanced excellent corrosion resistance by injection molding with rubber lining on all sides

Construction

Material

| No | Description | Material |

|---|---|---|

| 1 | BODY | Ductile cast iron |

| 2 | WEDGE | Ductile cast iron+EPDM |

| 2-1 | WEDGE GUIDE | DELRIN |

| 3 | BONNET | Ductile cast iron |

| 3-1 | BOLT, PW | Stainless steel |

| 4 | STEM | Stainless steel |

| 4-1 | BOLT, PW | Stainless steel |

| 4-2 | O-RING | NBR |

| 5 | PACKING BOX | Ductile cast iron |

| 5-1 | BOLT, NUT, PW | Stainless steel |

| 5-2 | O-RING | NBR |

| 5-3 | O-RING | NBR |

| 6 | GASKET | NBR |

| 7 | THRUST WASHER | DELRIN |

| 8 | STEM NUT | UNS C37700 |

| 9 | PAKING | NBR |

| 10 | CAP, HANDLE WHEEL | Ductile cast iron |

| 11 | INDICATOR | ASS'Y |

Dimensions

Flanges to KWWA, DIN F4 and F5, GOST, SABS, AS, BS and AWWA standards

| VALVE SIZE | A | √òC | D | ||||

|---|---|---|---|---|---|---|---|

| inch | mm | inch | mm | inch | mm | inch | mm |

| 2 | 50 | 7 | 178 | 6 | 150 | 5/8 | 16 |

| 2 1/2 | 65 | 7 1/2 | 191 | 7 | 180 | 11/16 | 17 |

| 3 | 80 | 8 | 203 | 7 1/2 | 190 | 3/4 | 19 |

| 4 | 100 | 9 | 229 | 9 | 230 | 15/16 | 24 |

| 6 | 150 | 10 1/2 | 267 | 11 | 280 | 1 | 25 |

| 8 | 200 | 11 1/2 | 292 | 13 1/2 | 340 | 1 1/8 | 29 |

| 10 | 250 | 13 | 330 | 16 | 410 | 1 3/16 | 30 |

| 12 | 300 | 14 | 356 | 19 | 483 | 1 1/4 | 32 |

| 16 | 400 | 16 | 406 | 23 1/2 | 597 | 1.44 | 37 |

| 20 | 500 | 18 | 457 | 27 1/2 | 699 | 1.69 | 43 |

| 24 | 600 | 20 | 508 | 32 | 813 | 1.88 | 47 |

| F | √òH | √òBCD | TORQUE(ft/lb) | NUM TURNS | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| No. | Bolt | Holes | inch | mm | inch | mm | ||||

| inch | mm | inch | mm | |||||||

| 4 | 5/8 | 16 | 3/4 | 19.1 | 2 | 50 | 4 3/4 | 120.7 | 25 | 7.7 |

| 4 | 5/8 | 16 | 3/4 | 19.1 | 2 1/2 | 60 | 5 1/2 | 139.7 | 29 | 9.5 |

| 4 | 5/8 | 16 | 3/4 | 19.1 | 3 | 80 | 6 | 152.4 | 33 | 10.7 |

| 8 | 5/8 | 16 | 3/4 | 19.1 | 4 1/4 | 110 | 7 1/2 | 190.5 | 44 | 13.7 |

| 8 | 3/4 | 19 | 7/8 | 22.2 | 6 1/4 | 160 | 9 1/2 | 241.3 | 59 | 19.6 |

| 8 | 3/4 | 19 | 7/8 | 22.2 | 8 1/4 | 210 | 11 3/4 | 298.5 | 88 | 25.6 |

| 12 | 7/8 | 22 | 1 | 25.4 | 10 1/4 | 260 | 14 1/4 | 362 | 110 | 31.5 |

| 12 | 7/8 | 22 | 1 | 25.4 | 12 1/4 | 310 | 17 | 431.8 | 132 | 37.5 |

| 16 | 1 | 25 | 1 1/8 | 28.5 | 16 1/8 | 410 | 21 1/4 | 539.8 | 184 | 50 |

| 20 | 1 1/8 | 28 | 1 1/4 | 31.8 | 20 1/8 | 510 | 25 | 635 | 253 | 61.9 |

| 20 | 1 1/4 | 31 | 1 3/8 | 35 | 24 1/8 | 610 | 29 1/2 | 749.3 | 325 | 73.8 |