- HOME

- PRODUCTS

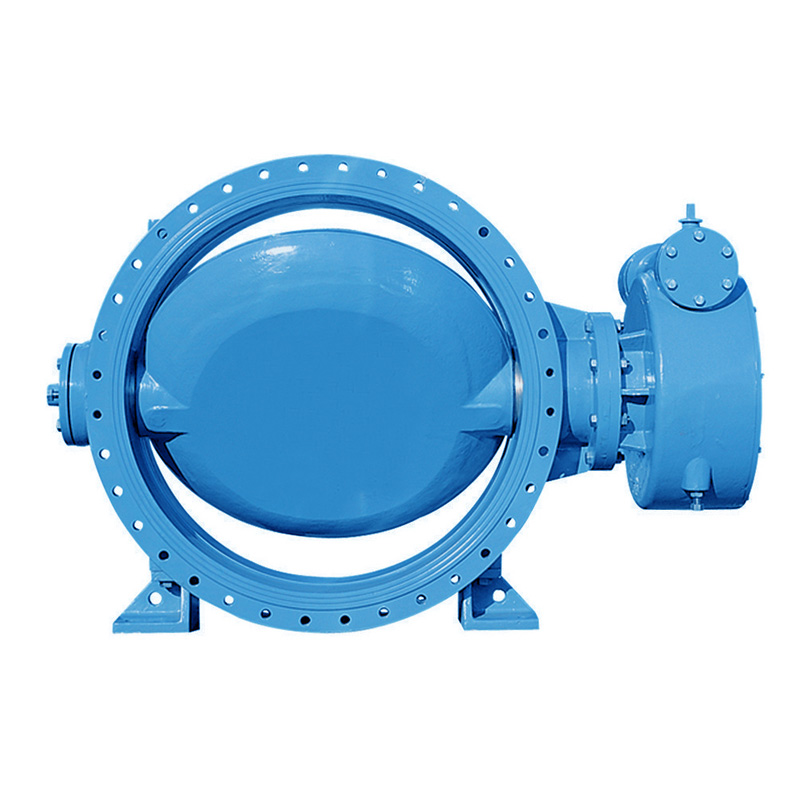

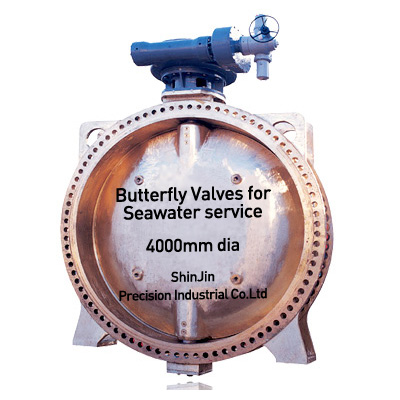

- Metal Seated Butterfly Valves

Warning: mysql_real_escape_string() [function.mysql-real-escape-string]: Access denied for user: 'nobody@localhost' (Using password: NO) in /home2/shinjinvalve/public_html/mobile/sub/sub_header.php on line 132

Warning: mysql_real_escape_string() [function.mysql-real-escape-string]: A link to the server could not be established in /home2/shinjinvalve/public_html/mobile/sub/sub_header.php on line 132

Metal Seated Butterfly Valves

Design features (Characteristic)

Mainlined performance over a long period and under severe service conditions

Precision-machined valve seat ensures an excellent watertight seal

- The shape of the metal seat was designed to cope with deformation of the valve body and the disc caused by fluid pressure inside the valve. The tapered cylinder is machined by numerically controlled lathe to ensure excellent watertight seals even after a long, hard service.

High corrosion resistance and durability

New stainless steel material for metal seat

- Special new material has been selected for the combination of valve body and disc, to minimize the galling effect of valve seat with an aim of improving durability, based on the analysis of friction science conducted by industry-academic cooperation.

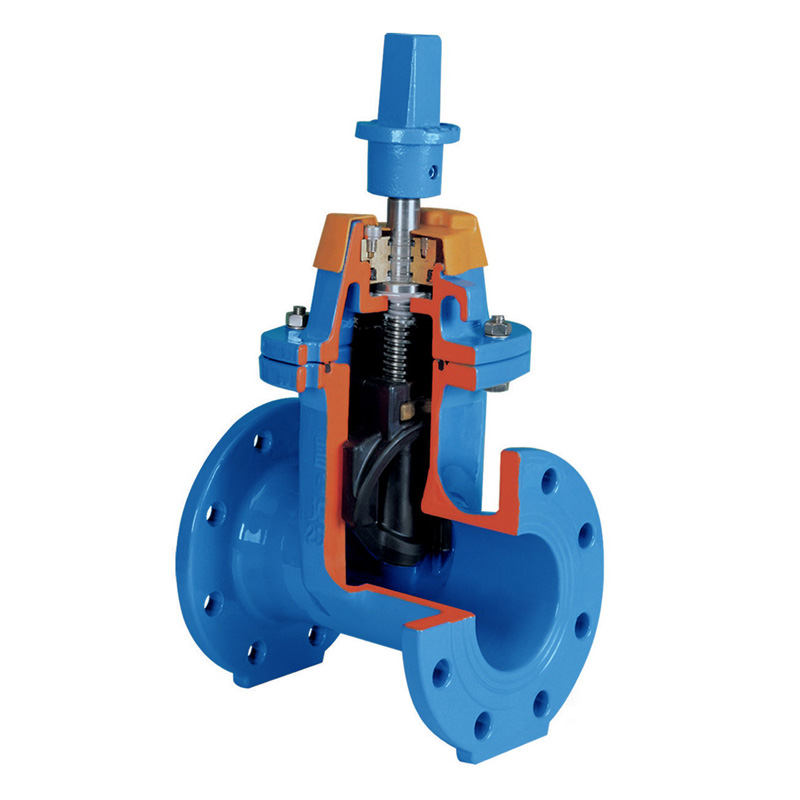

Effective leak-proof design

Shaft sealing for reliable watertight seal

- Newly developed leak-proof feature and effective structural design for shaft sealing ensures watertight seals and durability by effective sealing and maintained lubrication, even after extended use under severe working conditions.

Allowable leakage

Less than 1 oz/hr/in(=1.2„éñ/hr/mm) of nominal valve size(Reference AWWA C500)

Smooth valve opening and closing

Concentric disc and thrust bearing

- Concentric shaft center enables uniform distribution of fluid pressure, special dry bearing and four thrust bearings on the actuator smoothes valve opening and closing.

High corrosion resistance

Powder coated epoxy resin

- For highly effective corrosion resistance and rust proofing, both internal and external parts of the valve are powder coated using a proven epoxy resin product

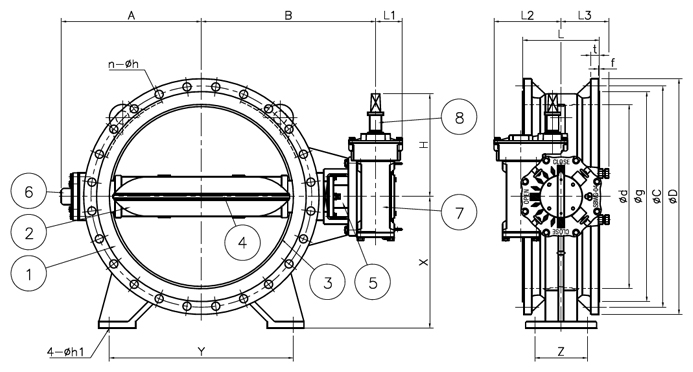

Construction

Material

| No | Description | Material |

|---|---|---|

| 1 | Body | Ductile iron GCD450 |

| 2 | Disc | Ductile iron GCD450 |

| 3 | Body Seat | Stainless steel STS304 |

| 4 | Disc Seat | Special Stainless steel |

| 5 | Shaft | Stainless steel STS420l2 |

| 6 | Left Cover | Carbonsteel SS400 |

| 7 | Gear Box | ASS’Y |

| 8 | Cap | Ductile iron GCD450 |

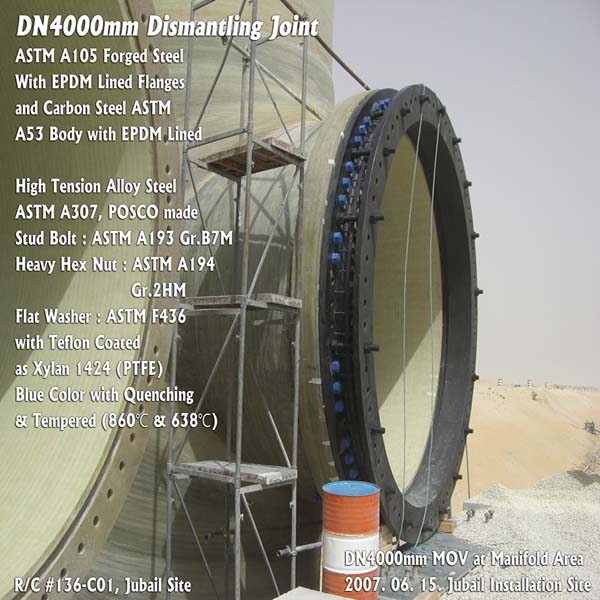

Dimensions

Flanges to KWWA, DIN F4 and F5, GOST, SABS, AS, BS and AWWA standards

| size(√òd) | √òD | √òC | √òg | n-√òh | L | t | f | A |

|---|---|---|---|---|---|---|---|---|

| 300 | 445 | 400 | 367 | 12-23 | 178 | 24 | 3 | 306 |

| 350 | 505 | 460 | 427 | 16-23 | 190 | 26 | 3 | 320 |

| 400 | 565 | 515 | 477 | 16-27 | 216 | 28 | 3 | 353 |

| 450 | 615 | 565 | 518 | 20-27 | 222 | 30 | 3 | 383 |

| 500 | 670 | 620 | 582 | 20-27 | 229 | 30 | 3 | 422 |

| 600 | 780 | 725 | 682 | 20-30 | 267 | 34 | 3 | 472 |

| 700 | 895 | 840 | 797 | 24-30 | 292 | 34 | 3 | 533 |

| 800 | 1015 | 950 | 904 | 24-33 | 318 | 36 | 3 | 606 |

| 900 | 1115 | 1050 | 1004 | 28-33 | 330 | 38 | 3 | 648 |

| 1000 | 1230 | 1160 | 1111 | 28-36 | 410 | 42 | 3 | 725 |

| 1100 | 1366 | 1270 | 1200 | 32-36 | 450 | 43 | 3 | 834 |

| 1200 | 1470 | 1387 | 1304 | 32-36 | 470 | 45 | 3 | 900 |

| 1350 | 1642 | 1552 | 1462 | 36-40 | 530 | 51 | 3 | 970 |

| 1500 | 1800 | 1710 | 1620 | 36-40 | 530 | 53 | 3 | 1082 |

| 1650 | 1950 | 1870 | 1770 | 40-40 | 700 | 58 | 3 | 1215 |

| 1800 | 2115 | 2020 | 1960 | 44-49 | 750 | 59 | 3 | 1290 |

| 2000 | 2325 | 2230 | 2170 | 48-49 | 800 | 62 | 4 | 1392 |

| 2200 | 2550 | 2440 | 2370 | 52-56 | 900 | 61 | 4 | 1495 |

| 2400 | 2760 | 2650 | 2570 | 56-56 | 900 | 64 | 4 | 1610 |

| 2600 | 2960 | 2850 | 2780 | 60-56 | 950 | 68 | 5 | 1730 |

| 2800 | 3180 | 3070 | 3000 | 64-56 | 1000 | 72 | 5 | 1850 |

| 3000 | 3405 | 3290 | 3210 | 64-56 | 1000 | 76 | 5 | 1970 |

| size(√òd) | B | X | Y | Z | 4-√òh1 | H | L1 | L2 | L3 |

|---|---|---|---|---|---|---|---|---|---|

| 300 | 478 | - | - | - | - | 265 | 51 | 150 | 150 |

| 350 | 493 | - | - | - | - | 265 | 51 | 150 | 150 |

| 400 | 523 | - | - | - | - | 265 | 51 | 150 | 150 |

| 450 | 550 | - | - | - | - | 289 | 60 | 150 | 150 |

| 500 | 518 | - | - | - | - | 320 | 75 | 188 | 148 |

| 600 | 583 | 450 | 600 | 180 | 23 | 320 | 75 | 188 | 175 |

| 700 | 633 | 500 | 700 | 200 | 23 | 370 | 102 | 255 | 181 |

| 800 | 793 | 550 | 800 | 230 | 23 | 403 | 102 | 197 | 248 |

| 900 | 798 | 600 | 900 | 240 | 27 | 400 | 102 | 282 | 215 |

| 1000 | 877 | 650 | 1000 | 250 | 27 | 499 | 153 | 383 | 287 |

| 1100 | 1187 | 700 | 1100 | 260 | 27 | 499 | 153 | 383 | 287 |

| 1200 | 1238 | 750 | 1200 | 270 | 27 | 504 | 153 | 297 | 386 |

| 1350 | 1166 | 825 | 1350 | 280 | 33 | 538 | 153 | 433 | 313 |

| 1500 | 1448 | 900 | 1500 | 300 | 33 | 681 | 194 | 534 | 371 |

| 1650 | 1635 | 1050 | 1650 | 320 | 33 | 1055 | 250 | 490 | 750 |

| 1800 | 1710 | 1100 | 1800 | 350 | 33 | 1055 | 250 | 490 | 750 |

| 2000 | 1813 | 1220 | 2000 | 400 | 33 | 1055 | 250 | 490 | 750 |

| 2200 | 1963 | 350 | 2200 | 450 | 39 | 1055 | 250 | 490 | 750 |

| 2400 | 2144 | 1450 | 2400 | 500 | 39 | 1266 | 310 | 680 | 1020 |

| 2600 | 2300 | 1550 | 2600 | 550 | 49 | 1266 | 310 | 680 | 1020 |

| 2800 | 2450 | 1670 | 2800 | 600 | 49 | 1266 | 310 | 680 | 1020 |

| 3000 | 2600 | 1790 | 3000 | 600 | 49 | 1266 | 310 | 680 | 1020 |