- HOME

- PRODUCTS

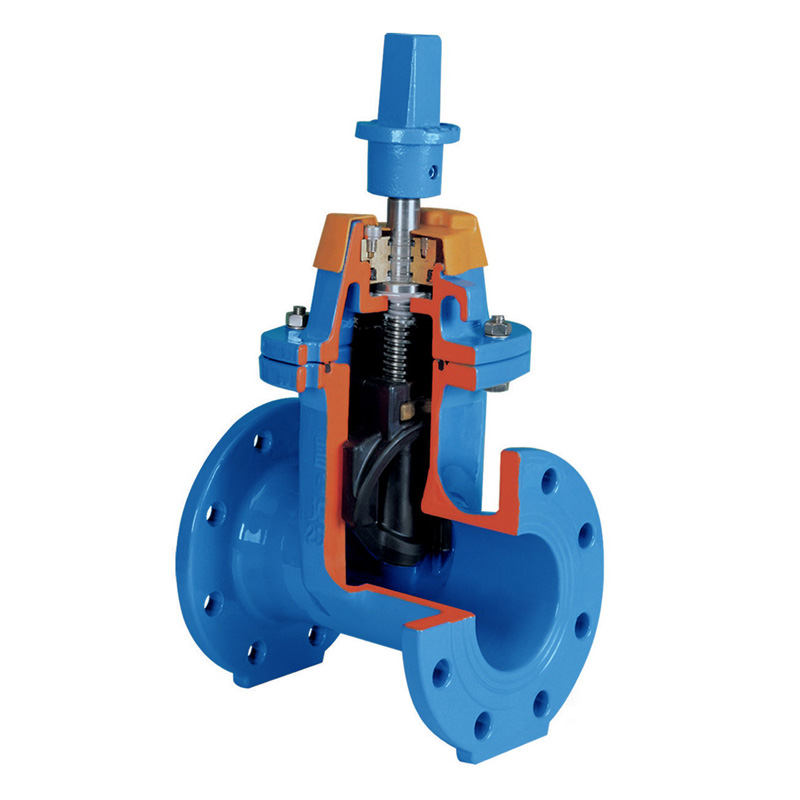

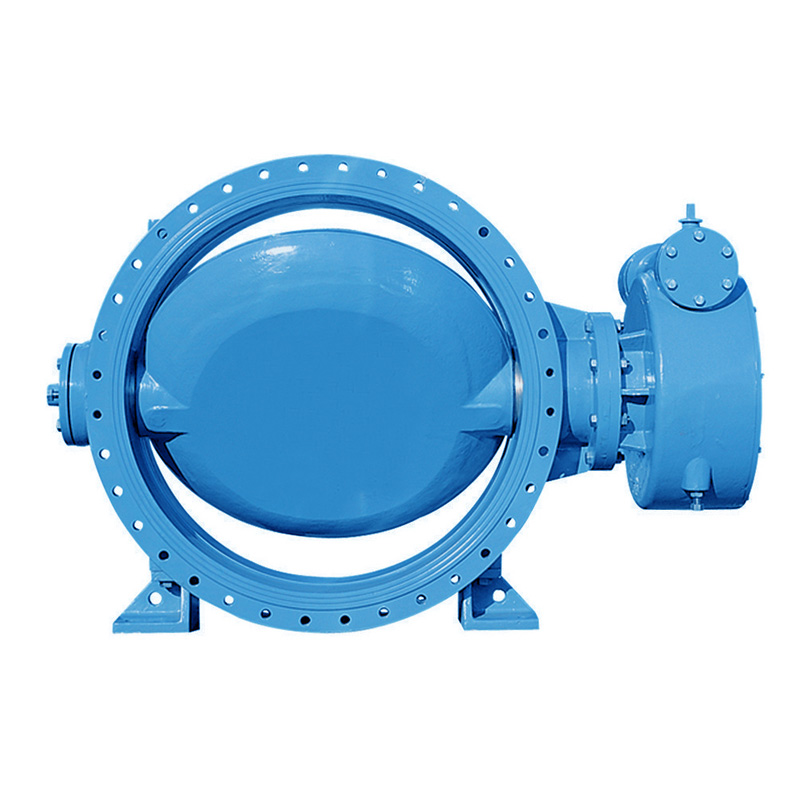

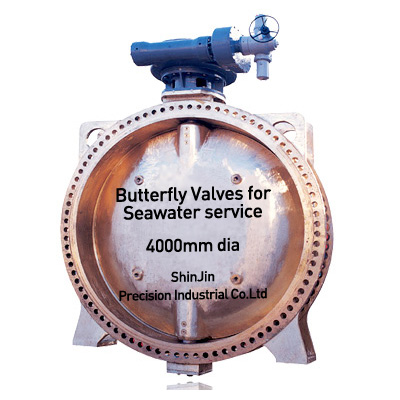

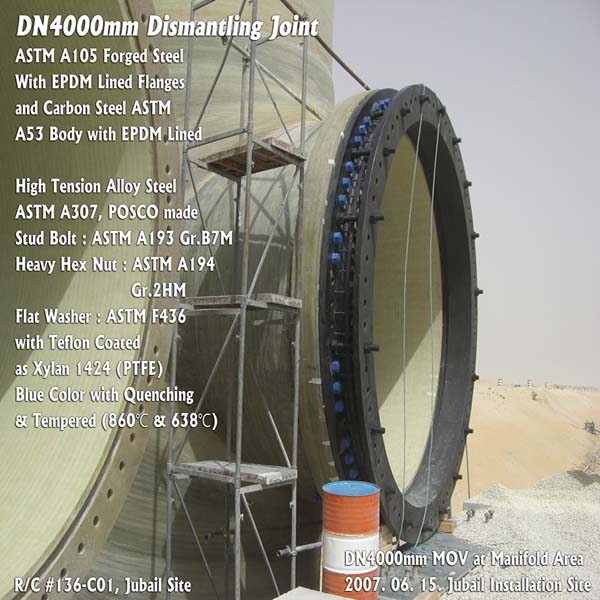

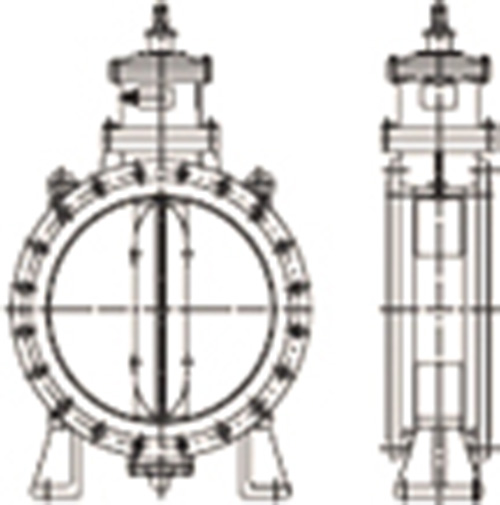

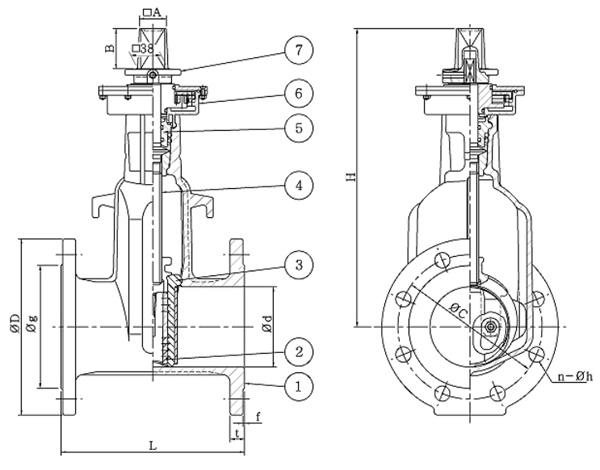

- Center Cap Type Metal Seated Butterfly Valves

Warning: mysql_real_escape_string() [function.mysql-real-escape-string]: Access denied for user: 'nobody@localhost' (Using password: NO) in /home2/shinjinvalve/public_html/mobile/sub/sub_header.php on line 132

Warning: mysql_real_escape_string() [function.mysql-real-escape-string]: A link to the server could not be established in /home2/shinjinvalve/public_html/mobile/sub/sub_header.php on line 132

Center Cap Type Metal Seated Butterfly Valves

Design features (Characteristic)

Three innovation

1. Reduce valve laying time

2. Reduce installation and maintenance cost

3. Increase valve reliability

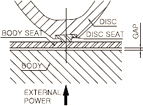

Flexible valve seat structure for laying

- Practical structure design of valve body and valve seat separated, so when laying, body strain from external force is absorbed by the body seat gap, not effecting water stop and operation.

Metal seat excellent in durability

- New material of special metal is selected for valve seat to minimize galling effect and cylindrical structure of high-tech precise machining enable excellent water stoppage even on long hours of overstrain.

8/

8/

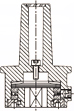

The cap to prevent over-torque for valve

(patent registration No. 10-0777003)

- Attached to the valve operator spindle to prevent in advance damage of valve operator or main valve and valve seat from cap idling on operation due to overload above operation setting.

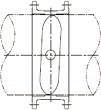

Easy pipe design and maintenance

- Valve operation cap is located in center of valve and duct spindle for no valve installing position limit and easy pipe design, and valve opening indication is easy, small, light, and excellent for inner environments, appropriate for laying.

Construction

Material

| No | Description | Material |

|---|---|---|

| 1 | BODY | Ductile iron GCD450 |

| 2 | DISC | Ductile iron GCD450 |

| 3 | DISC SEAT | Rubber EPDM |

| 4 | STEM | Stainless steel STS410 |

| 5 | PACKING BOX | Brass |

| 6 | INDICATOR BOX | ASS’Y |

| 7 | CAP | Ductile ironÔºö GCD450 |

Dimensions

Flanges to KWWA, DIN F4 and F5, GOST, SABS, AS, BS and AWWA standards

| size(√òd) | √òD | √òC | √òg | n-√òh | L | t | f | A | B | H | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| standard | Indicator | ||||||||||

| 80 | 200 | 160 | 133 | 4-19 | 203 | 18 | 2 | 33.5 | 50 | 310 | 341 |

| 100 | 220 | 180 | 153 | 8-19 | 229 | 18 | 2 | 33.5 | 50 | 342 | 372 |

| 150 | 285 | 240 | 209 | 8-23 | 267 | 22 | 2 | 33.5 | 50 | 428 | 459 |

| 200 | 340 | 295 | 264 | 8-23 | 292 | 22 | 2 | 33.5 | 50 | 515 | 545 |

| 250 | 395 | 350 | 319 | 12-23 | 330 | 24 | 2 | 33.5 | 50 | 611 | 640 |

| 300 | 445 | 400 | 367 | 12-23 | 356 | 24 | 3 | 33.5 | 50 | 695 | 723 |

| 350 | 506 | 460 | 427 | 16-23 | 381 | 26 | 3 | 32 | 70 | 877 | 909 |

| 400 | 565 | 515 | 477 | 16-28 | 406 | 27 | 3 | 32 | 70 | 959 | 990 |

| 500 | 670 | 620 | 582 | 20-28 | 457 | 29 | 4 | 32 | 70 | 1137 | 1169 |